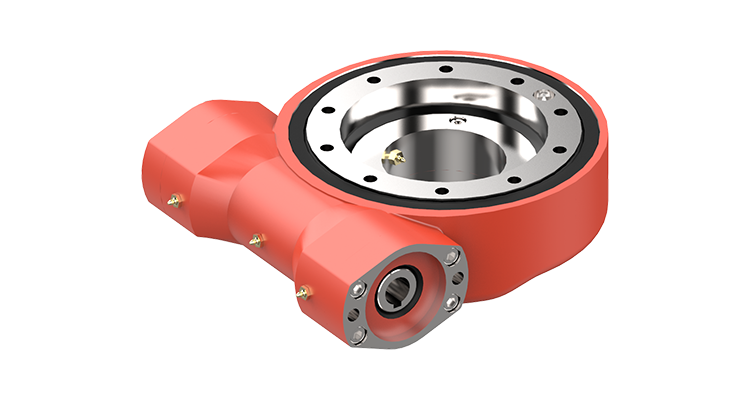

The WEA series slewing ring bearing with integrated worm gear is suitable for industrial applications where high torque is required at a low rotational speed.

Call us: +31 (0) 252 228850

Product overview

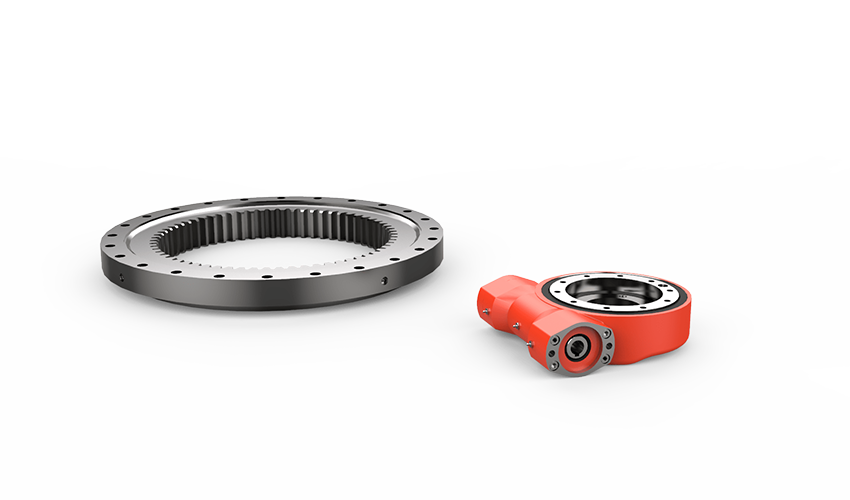

Slewing Drives

Slewing ring bearings with integrated worm gear

Type WEA

| Outside diameter | 231 – 744 [mm] |

| Ratio | 47 – 104 |

| Tilting moment | 14,2 – 310 [kNm] |

| Max output torque | 3,5 – 34,2 [kNm] |

| Max holding torque | 20 – 158,3 [kNm] |

| Max output speed | 0 – 2,5 [rpm] |

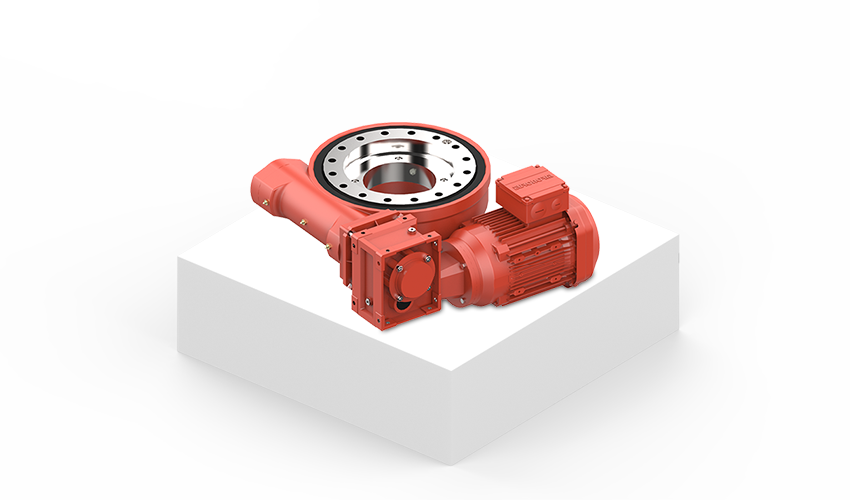

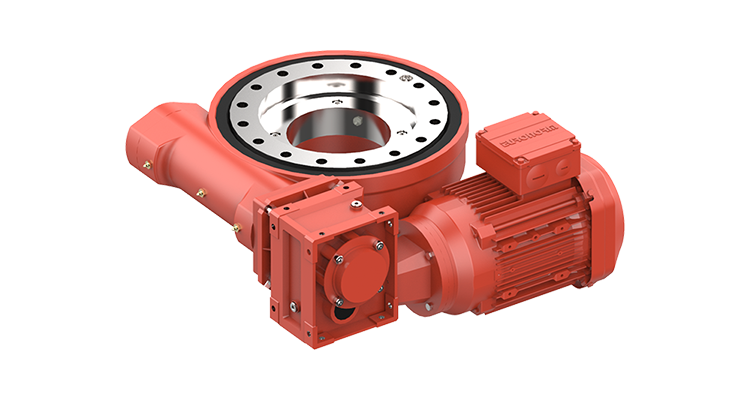

Slewing ring drive with gearbox & electric motor

Type WEA

| Outside diameter | 231 – 744 [mm] |

| Ratio | 47 – 104 |

| Tilting moment | 14,2 – 310 [kNm] |

| Max output torque | 3,5 – 34,2 [kNm] |

| Max holding torque | 20 – 158,3 [kNm] |

| Max output speed | 0 – 1 [rpm] |

Product Info

Slewing Drives

The WEA series slewing ring bearings with integrated worm gear can be provided with an IEC or hydraulic motor mounting flange and are therefore versatile in application.

This type of slewing ring is mainly used in ‘heavy’ applications, such as where a lot of axial force and moment must be absorbed. You can think of industrial boat cranes, excavators, turntables and grabs.

Due to the integrated worm gear, a high torque can be achieved at a low rotational speed, in addition, the worm helps with the self-locking of the slewing ring.

There is also the option of mounting a pre-stage to increase the transmission, which can be used in applications where the slewing ring must be positioned very accurately.

Quality

Due to the constant high quality and competitive pricing, the Euronorm worm gear reducer is a very suitable drive for use in machines and production processes.

The quality of the slewing ring bearings is guaranteed by production exclusively under UNI EN ISO 9001:2008. Supplied materials are also strictly controlled and selected for their proven quality.

Stock

Euronorm keeps a large number of worm gears in stock and can deliver them quickly. In addition, there is a very wide availability of various motors and other drives.

Euronorm is also able to make modifications, assemble drives and spray paint in accordance with the customer’s wishes in its own workshop. All this within a limited time and from stock.